In the traditional metal casting process in foundries, trials and errors at prototyping and product launch may incur the waste of material, labour, increased lead times to arrive at the optimal design that gives the desired quality and yield. With the advent of the modern competitive technological and commercial environments, casting users want foundries to deliver high-quality components in shorter lead times. To meet the growing demands, foundry trials have given way for computer simulation of casting processes for analysing and optimising the component design on users’ personal computer at the design phase. ADSTEFAN’s analysis tools not only include practical and affordable fluid flow analysis and solidification analysis but also offer the Advanced Defect Prediction Tool (ADPT) option using machine learning.

The advanced defect prediction tool (ADPT) via tech-enabled defect prediction database comes with myriad benefits.

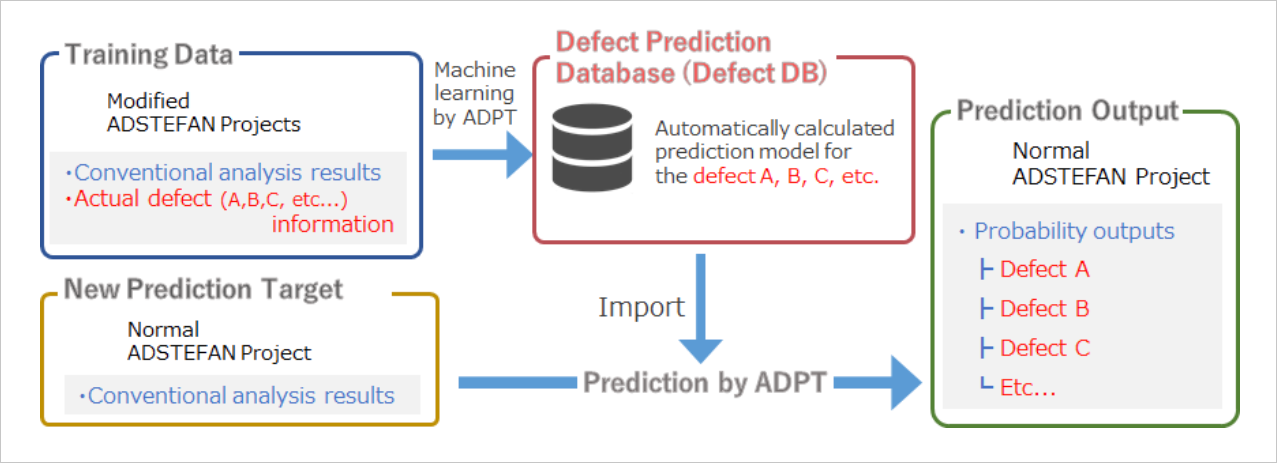

Casting simulation software, ADSTEFAN’s Advanced Defect Prediction Tool (ADPT) predicts defect occurrence probabilities in a new casting part by utilizing a defect prediction database generated by machine learning and retaining the defect and testing experiences in it for future defect predictions.

A robust casting simulation software must demonstrate its ability to analyse the time-bound changes in fluid flow and solidification with accuracy and predict the defects and thereby help foundries get insights for improved casting quality beforehand.

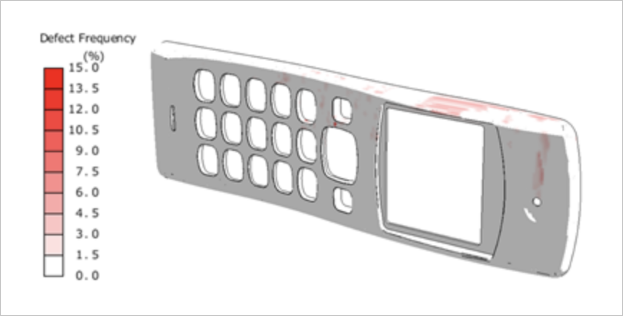

ADSTEFAN’s Advanced Defect Prediction Tool (ADPT) uses actual casting defect information and analysis results as ‘teaching data’ to build a defect prediction database by using machine learning, then outputs the probability of the defects considering the actual shop floor environment. The prediction model is directly linked to the actual defect information therefore it reduces ‘fitting’ and ‘modelling’ errors between what is happening on the shop floor and what is simulated on CAE, and gives a more accurate prediction for casting defects and testing results. By leveraging the power of machine learning, ADPT models the relations between physical phenomena and defects that casting engineers could only guess by their experiences and intuitions and evaluates the defect probabilities which have been conventional challenges in matching and interpreting the results.

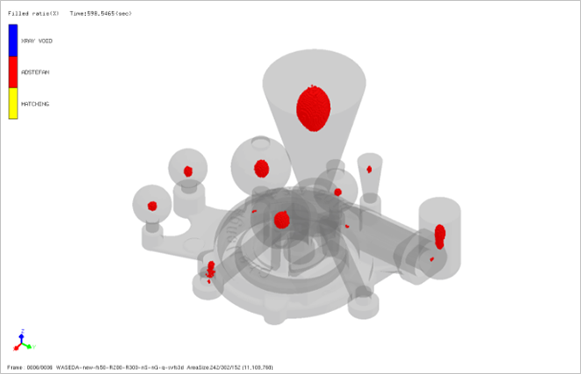

Advanced Defect Prediction Tool by ADSTEFAN enhances prediction accuracy of the most common casting defects in the earliest stages of design, which include shrinkage porosity, air entrapment, cold shut, hot tear, and misruns.

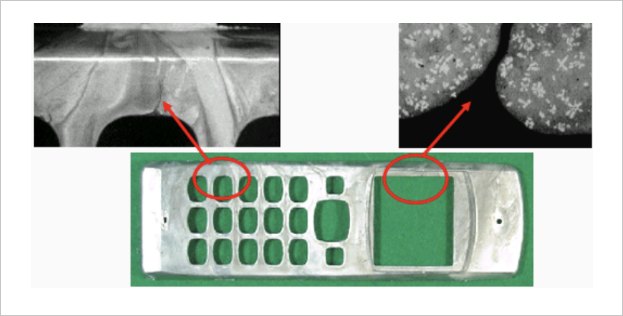

Example of defect prediction (Cold Shut)

We are here to help you.

Contact Us