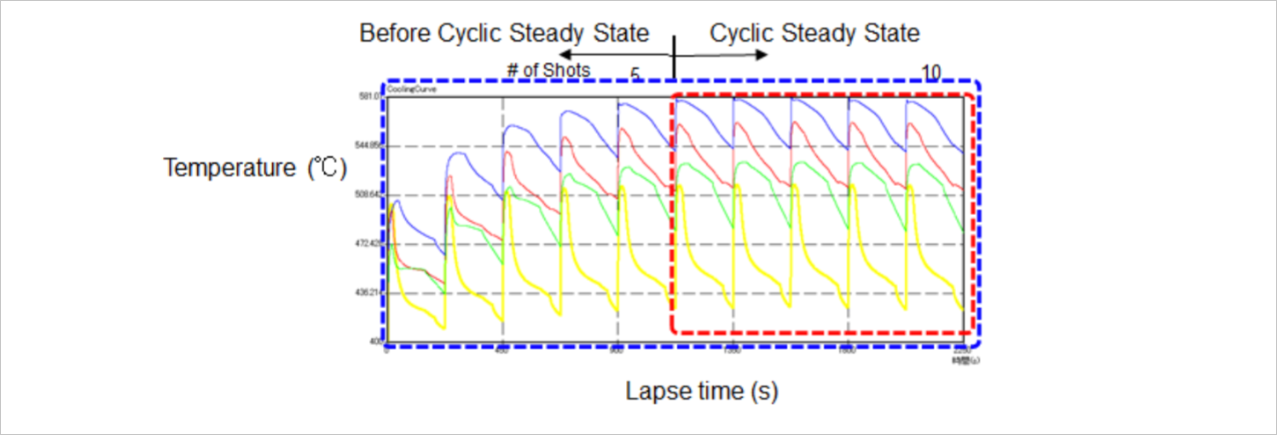

For effective solidification analysis for the die-casting, it is essential to consider the reliability of the initial die temperature required to input into the simulation software. Typically the die temperature fluctuates and increases through cycles of casting and spray cooling until the die undergoes more or less ten shots and the temperature reaches a cyclic steady state. On conventional simulation, this means running die temperature analysis ten times to get a reliable initial die temperature for solidification analysis. Die temperature analysis like this is precise but also time-consuming. Cyclic Steady heat balance Method (CSM) is a unique component of casting simulation software ADSTEFAN. It is used for a quick determination of the mean temperature distribution of a die at a cyclic steady state in die-casting, which can be used as the initial die temperature for solidification analysis.

After several shots, the die temperature achieves a cyclic steady state, whose mean temperature CSM calculates.

Throughout die casting processes, repeated casting and spray cooling vary the temperature of a die in a cyclic pattern. This temperature variation usually achieves a cyclic steady state after about ten cycles. The Cyclic Steady heat balance Method (CSM) is a thermal analysis method adopted by ADSTEFAN to predict the mean die temperature distribution at a cyclic steady state. Unlike die temperature analysis, CSM does not calculate time-series changes in die temperature in detail, but it shows the die temperature distribution with which to start solidification analysis quickly and reliably without repeated numerical calculation.

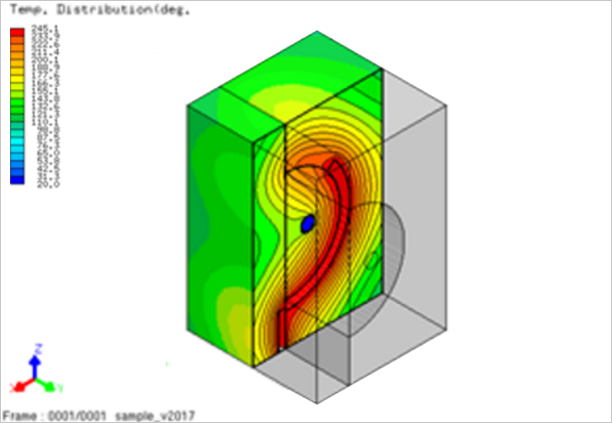

By inputting the mean temperature distribution calculated on CSM as the initial temperature, solidification analysis becomes less painstaking but still effective. CSM saves time and energy to run a dozen shots of die temperature analysis to get the steady-state die temperature distribution. If several shots of die temperature analysis are run after CSM, the die temperature distribution becomes almost as reliable as the die temperature received after a dozen shots of die temperature analysis, which decreases the calculation duration for the initial die temperature for solidification analysis.

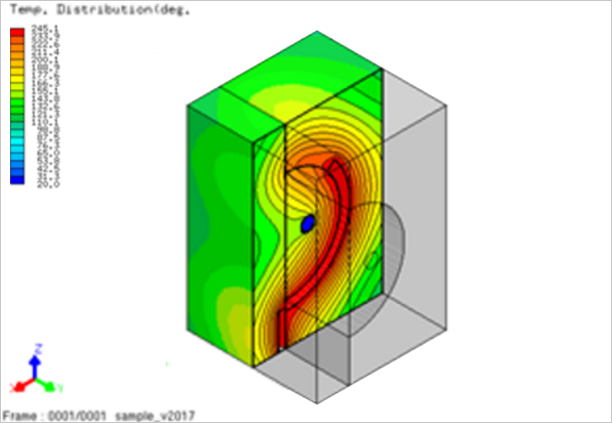

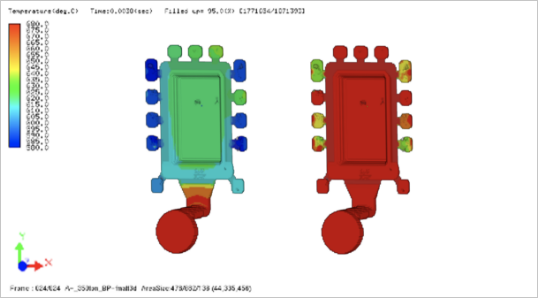

An example of die temperature distribution with CSM only (temperature range: 20.0 to 245.1 ℃)

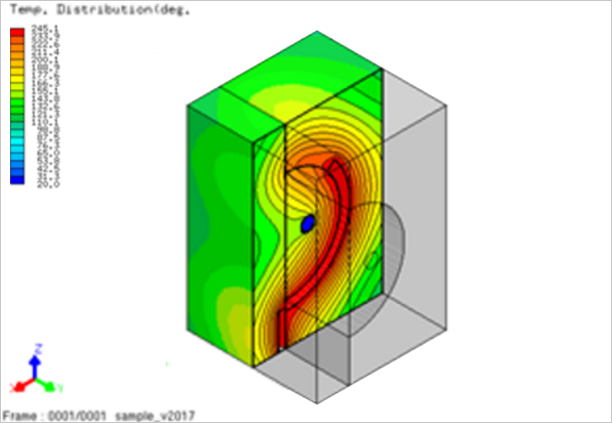

The same example with fifteen cycles of die temperature analysis (temperature range: 20.0 to 225.1 ℃).

The same example with five cycles of die temperature analysis after CSM (temperature range: 20.0 to 225.1℃)

CSM enhances the die casting solidification analysis as it supplies a good approximation of the initial die temperature distribution. The number of die-cast cycles needed for calculating the steady-state is drastically reduced by using CSM, which can be used as the initial state for solidification analysis.

ADSTEFAN’s ability to quickly calculate the mean die temperature distribution at a cyclic steady state allows for efficiency in solidification analysis. The calculation becomes more reliable if CSM is combined with several shots of die temperature analysis, which is another function of ADSTEFAN.

We are here to help you.

Contact Us